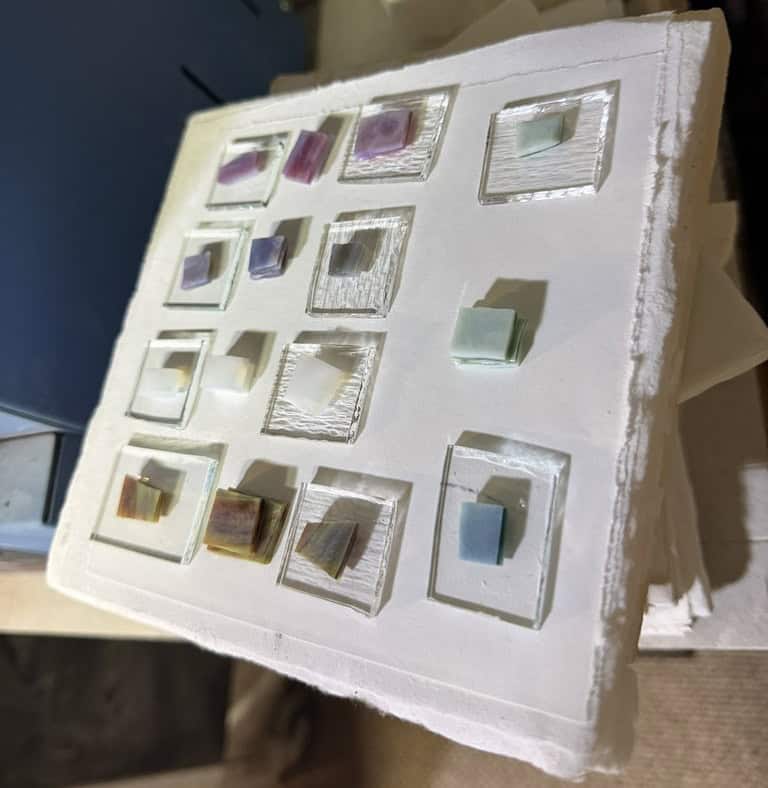

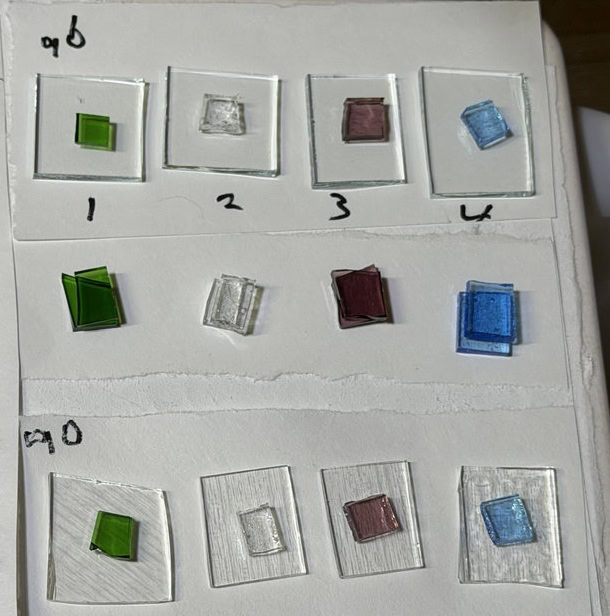

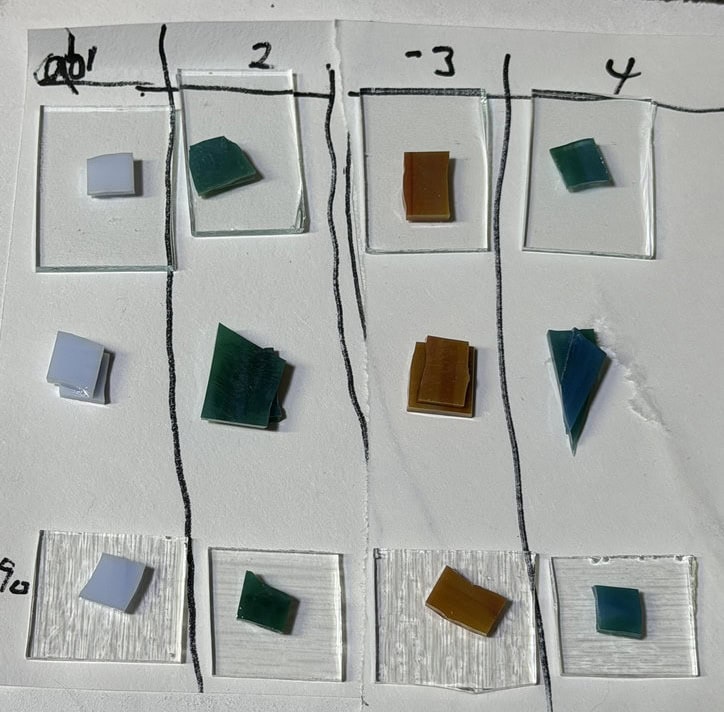

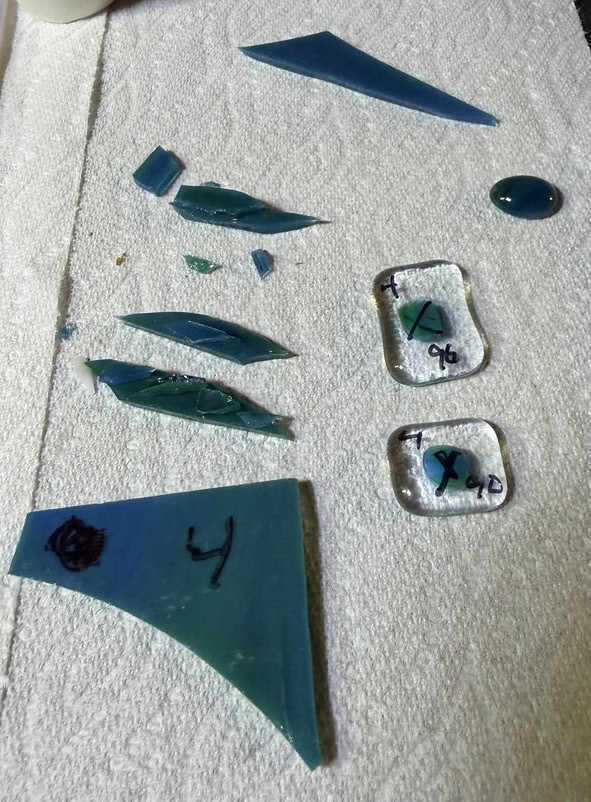

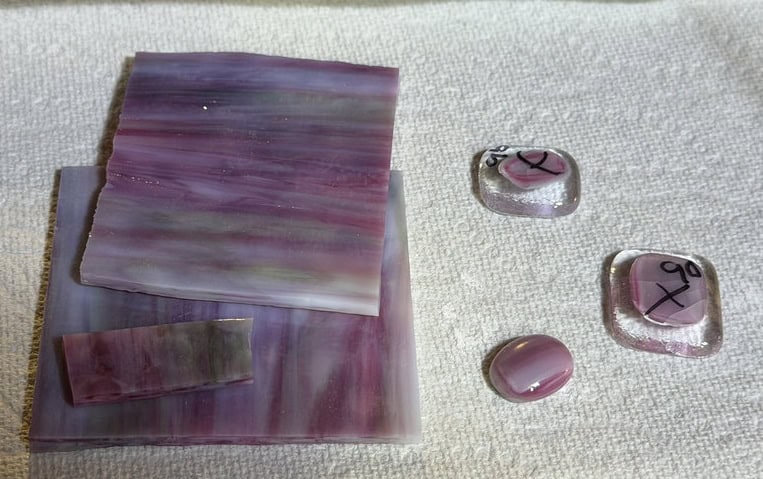

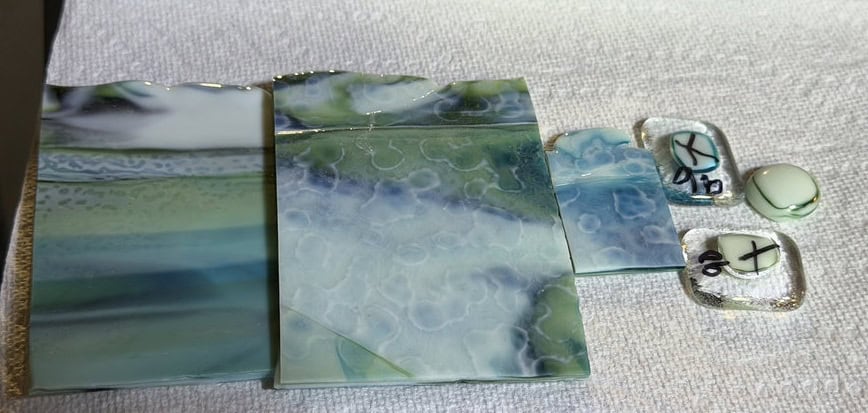

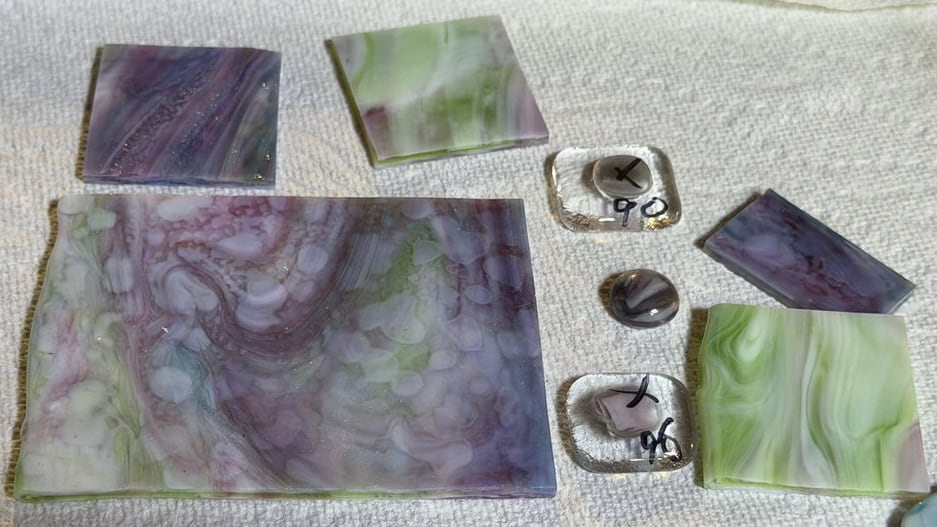

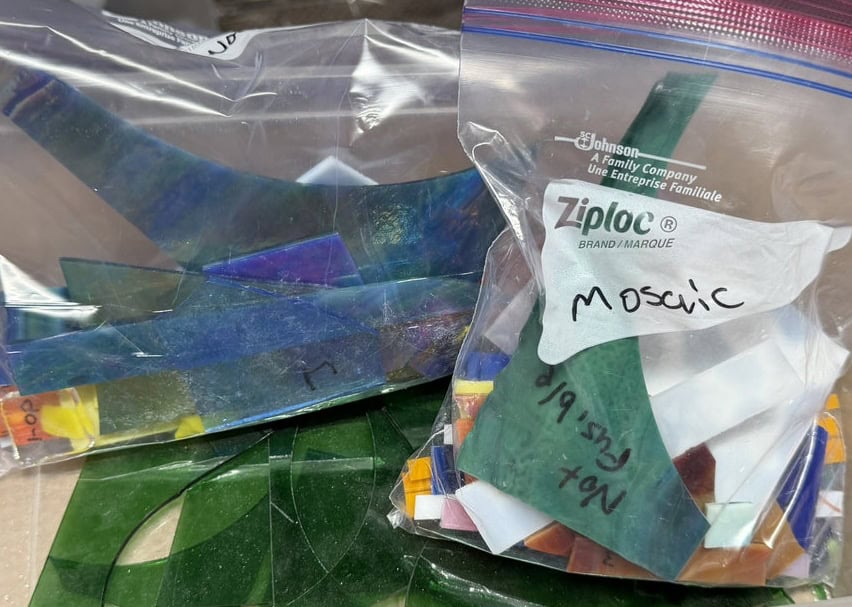

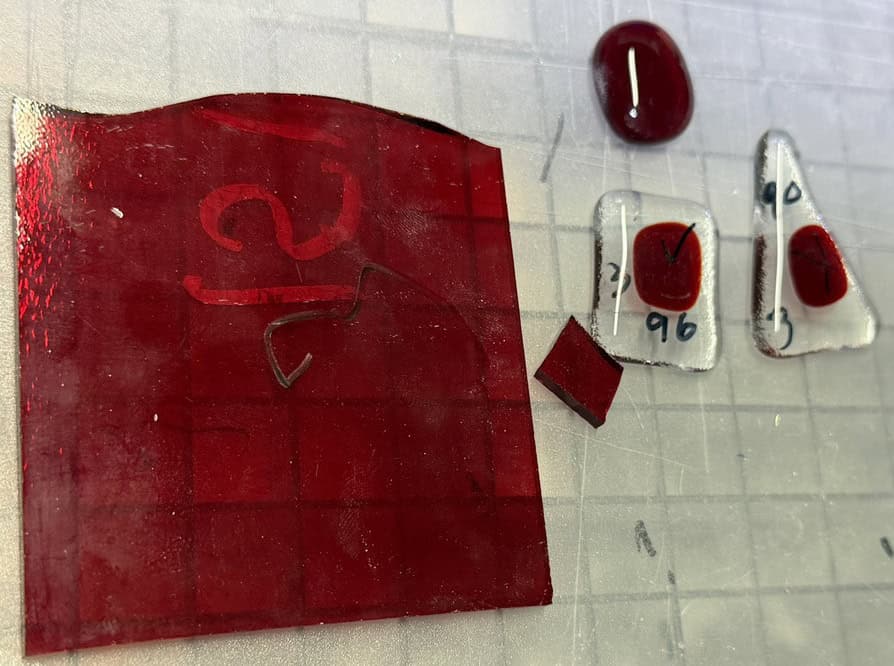

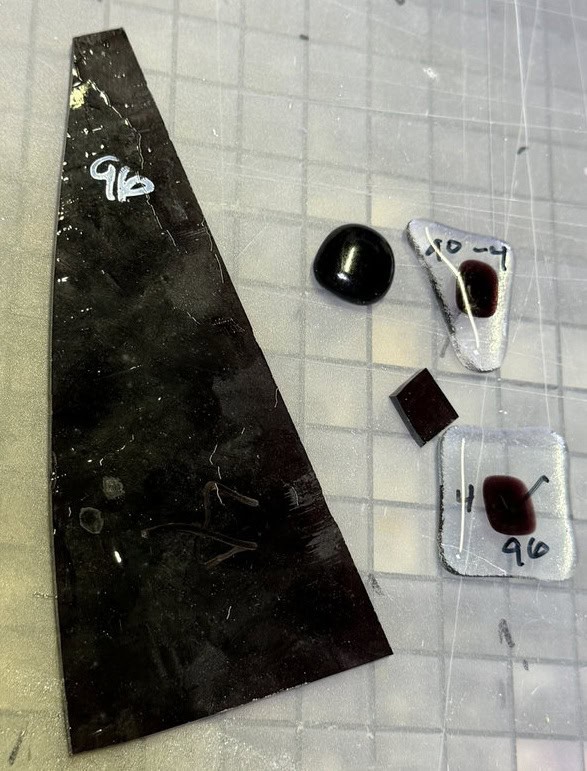

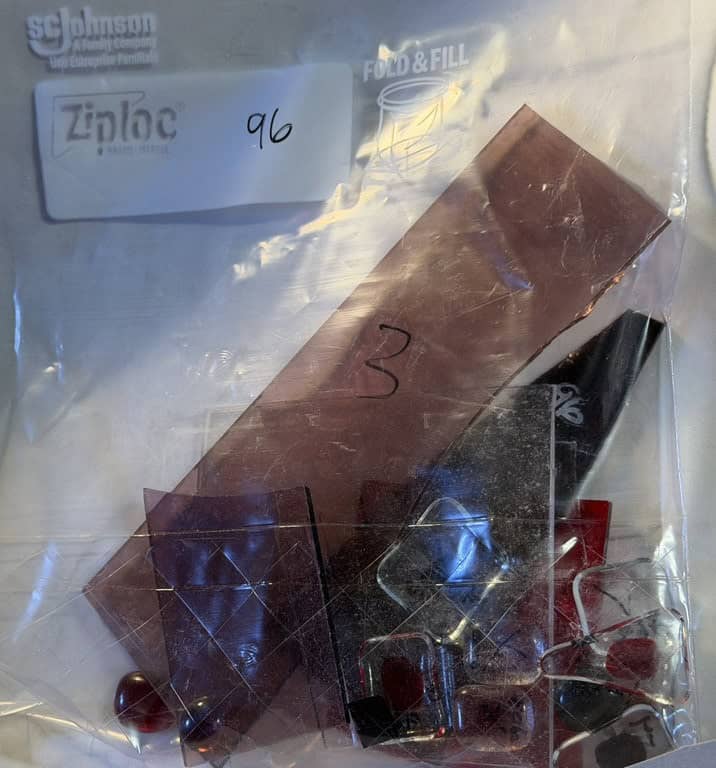

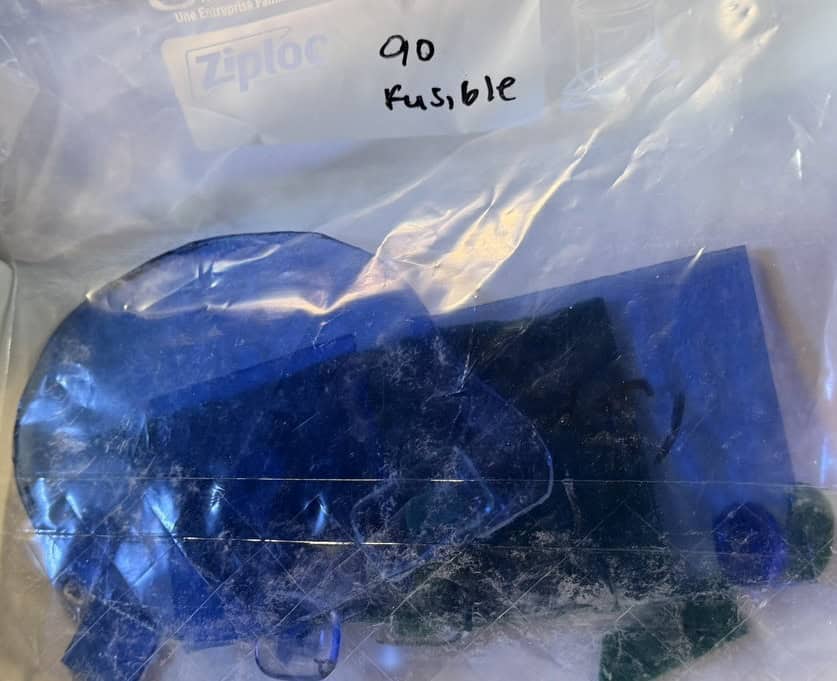

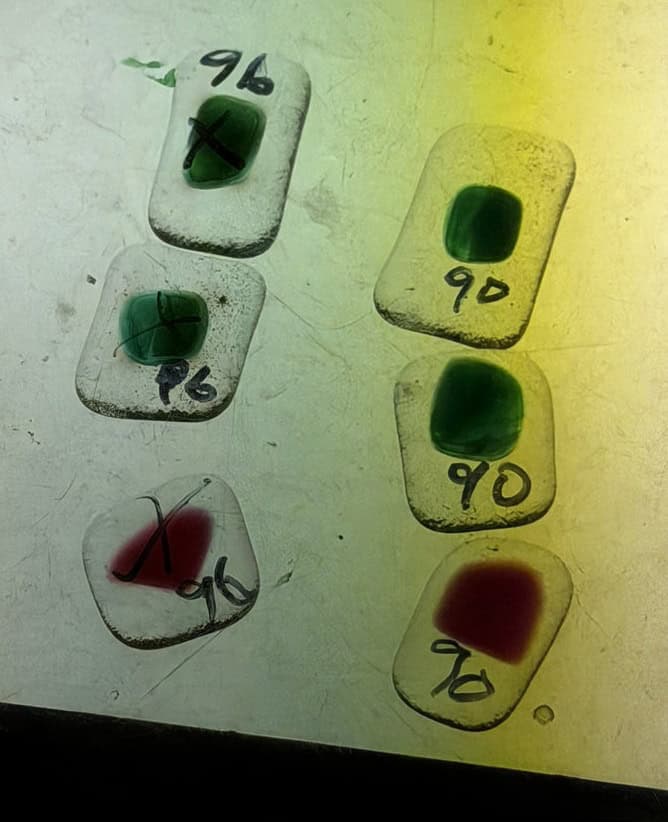

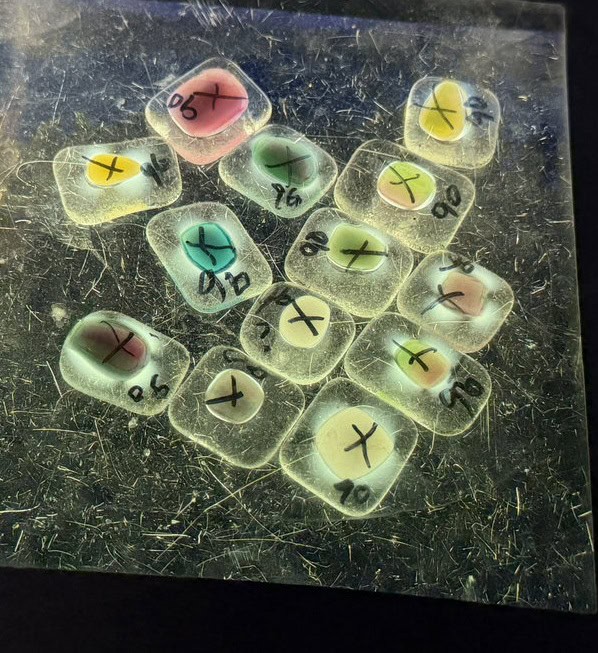

I love glass — all glass. And if you’re a glass artist, you know exactly what that means… sometimes beautiful sheets of glass follow me home even when they aren’t labeled for fusing. I do my best to keep my fusible glass organized by COE, but once in a while I end up with mystery glass — usually stained glass or mosaic glass that I’m not completely sure is compatible. Rather than risk cracking a finished piece, I test it first. My go-to compatibility test is simple but effective. I take a small piece of the unknown glass and place it on both COE 90 and COE 96 base glass. I also place a small piece of the mystery glass on top of itself to see how it behaves in a full fuse. Some stained glass will fuse beautifully to itself but won’t play nicely with fusible glass — and other times it does the opposite. Below you can see the test setup before firing on the left, and the same shelf after fusing on the right. This little test saves a lot of heartbreak later!

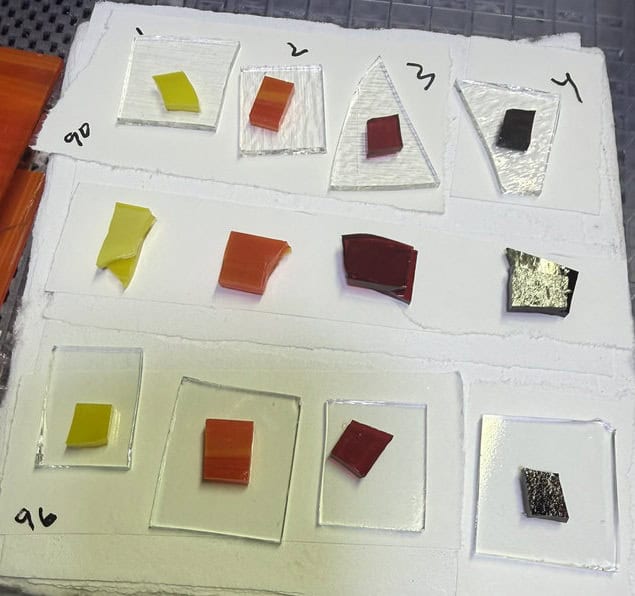

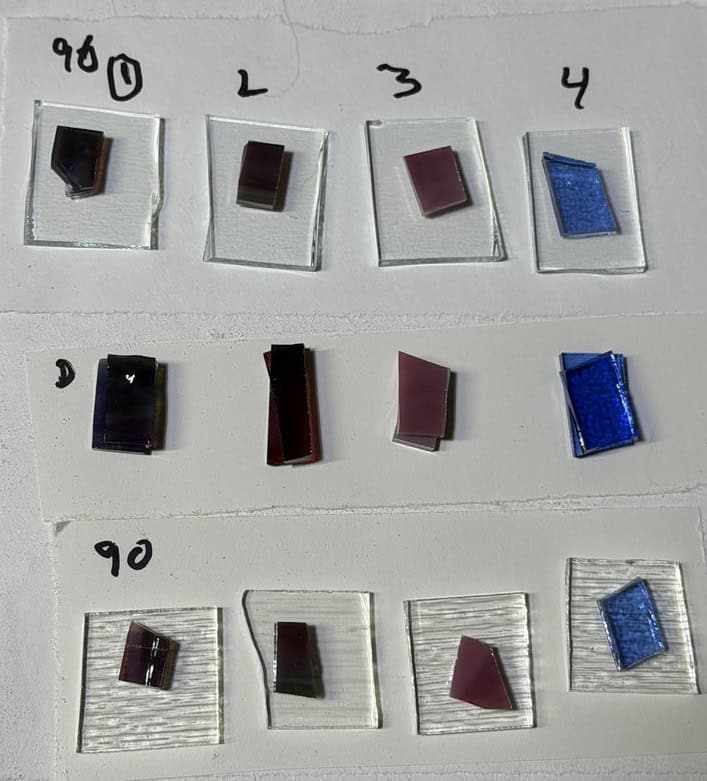

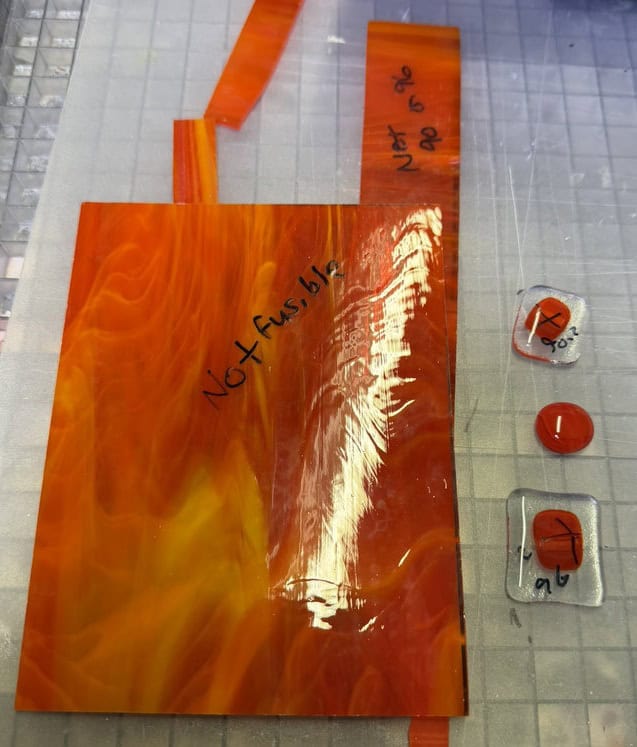

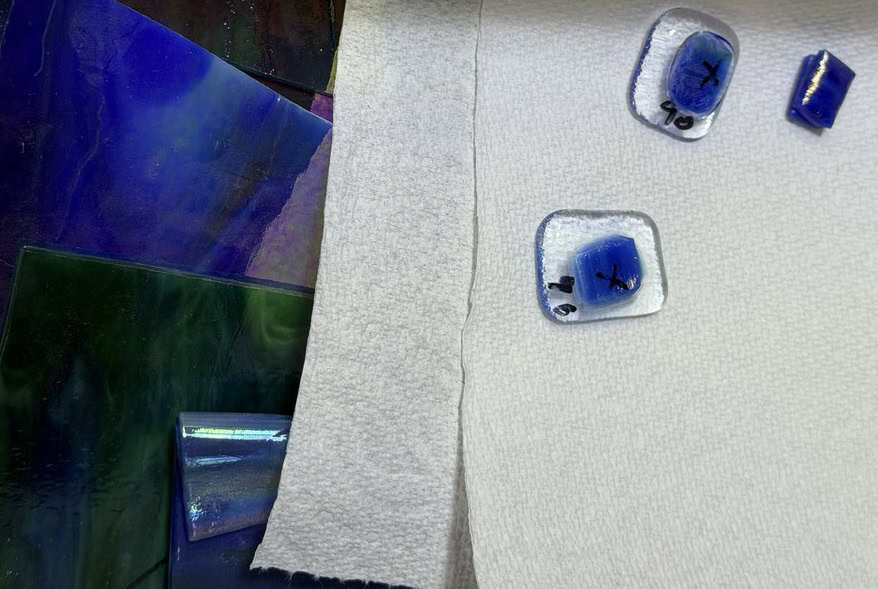

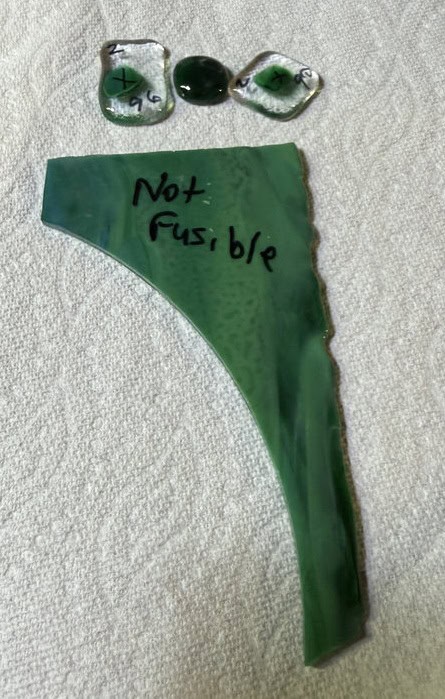

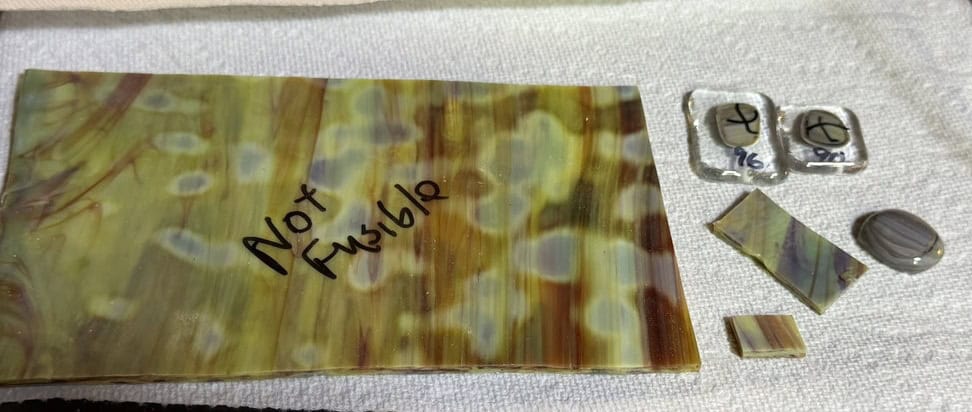

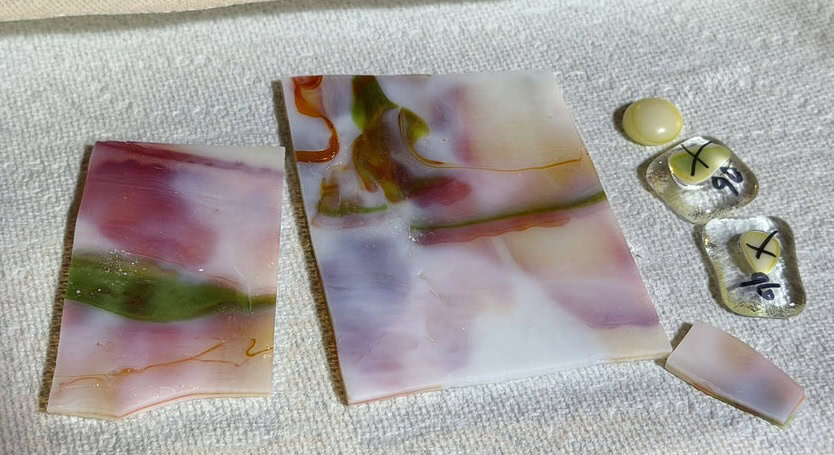

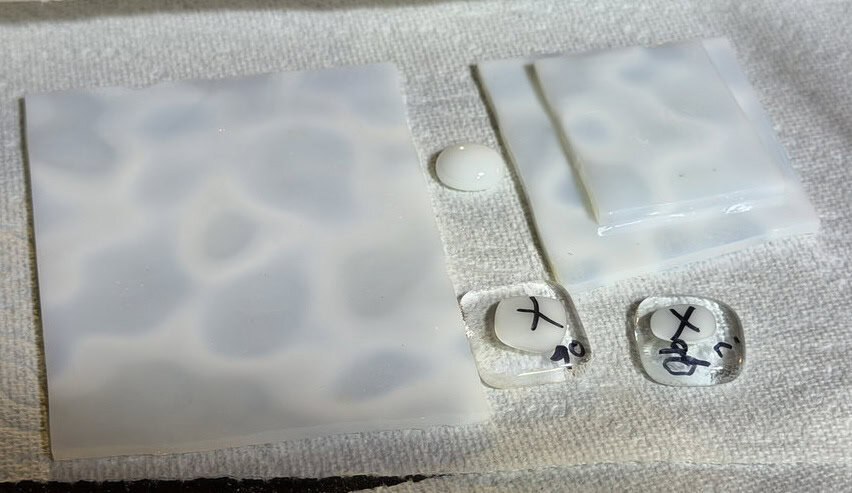

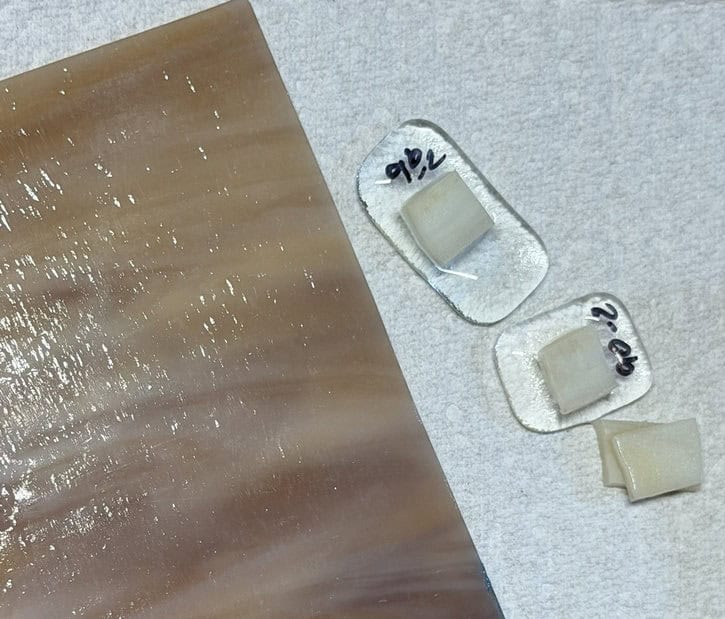

This next group of photos shows the glass that turned out not to be compatible with either COE 90 or COE 96. If you look closely, you can see how some of the pieces didn’t fully fuse together, leaving rough edges, separation lines, or uneven surfaces. In a finished project, this kind of incompatibility would lead to weak spots or cracking over time. These results tell me that this glass is best left for stained glass or mosaic work rather than kiln-fused projects — and that’s exactly why testing is so important.

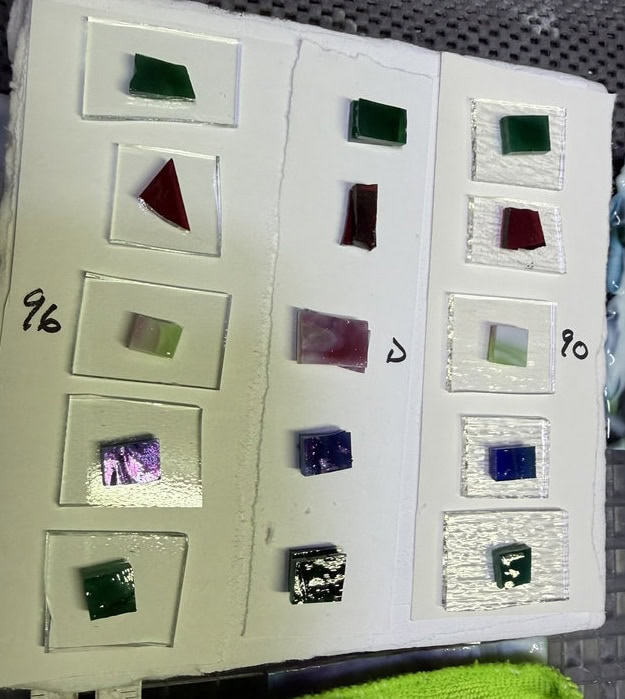

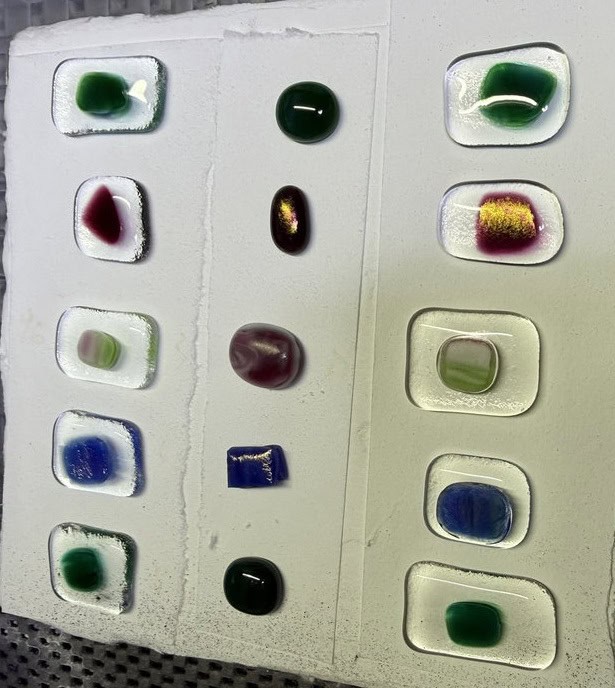

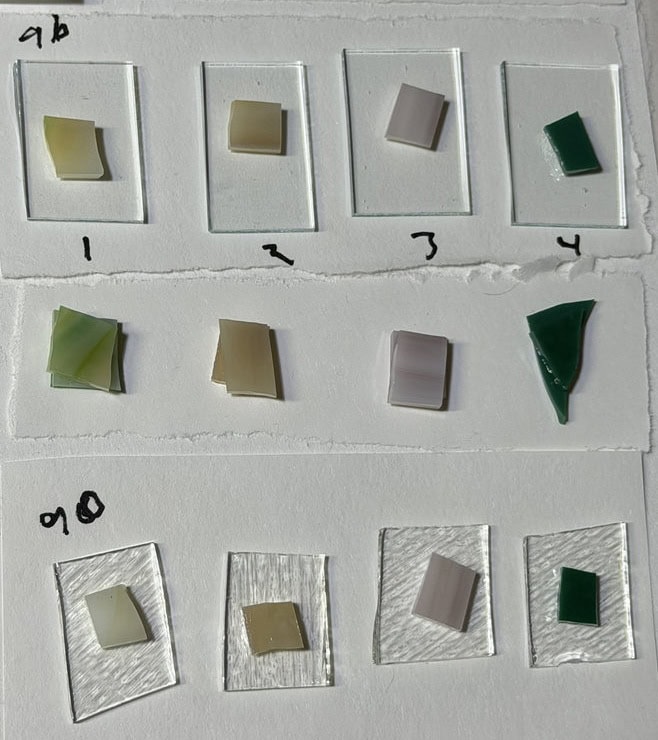

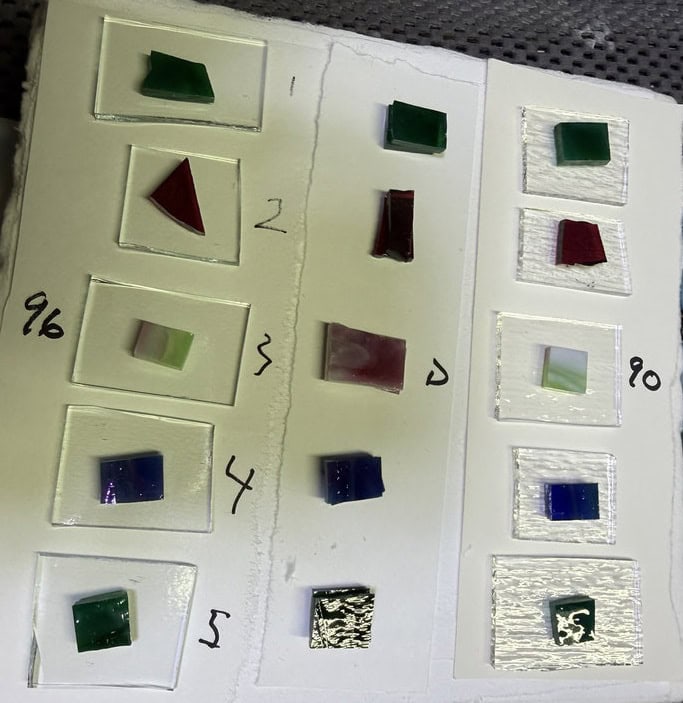

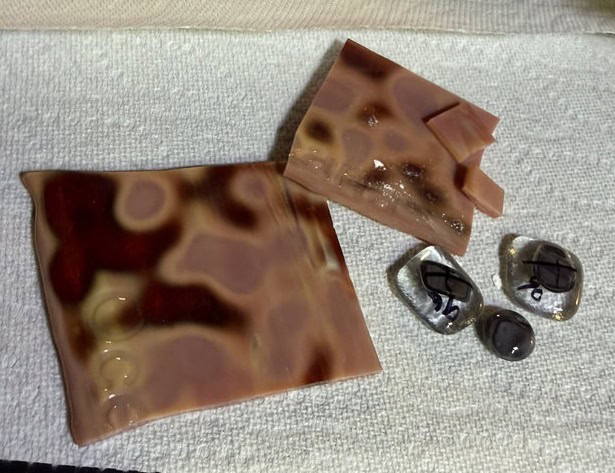

This next group of photos shows the glass that did turn out to be compatible with either COE 90 or COE 96. And honestly… not a lot made the cut! But that’s exactly why testing matters. These pieces fused smoothly, stayed flat, and showed no signs of stress or separation after cooling — all good indicators of proper compatibility. Any of this glass can now be safely used in future fused projects without worry.

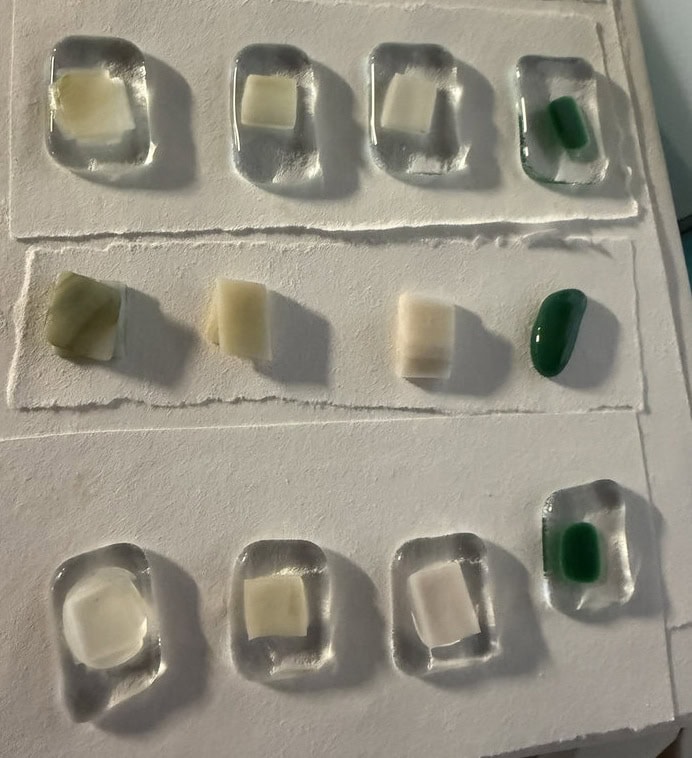

Here are a few more test results showing glass that doesn’t fuse well — even to itself. You can see areas where the pieces refused to melt smoothly together, leaving rough or separated surfaces. Glass like this is unpredictable in the kiln and not suitable for fused projects, no matter how pretty it may look in sheet form. In contrast, some of the mystery glass fused beautifully to itself, even though it isn’t compatible with COE 90 or COE 96. That means it could still be useful for projects where it’s fused only to itself, such as small decorative pieces. You may also notice a bit of devitrification on some samples — a hazy or crystalline surface that can appear when certain glasses are fired. Even with a little devit, these pieces fused well structurally, which gives me valuable information for future experiments.

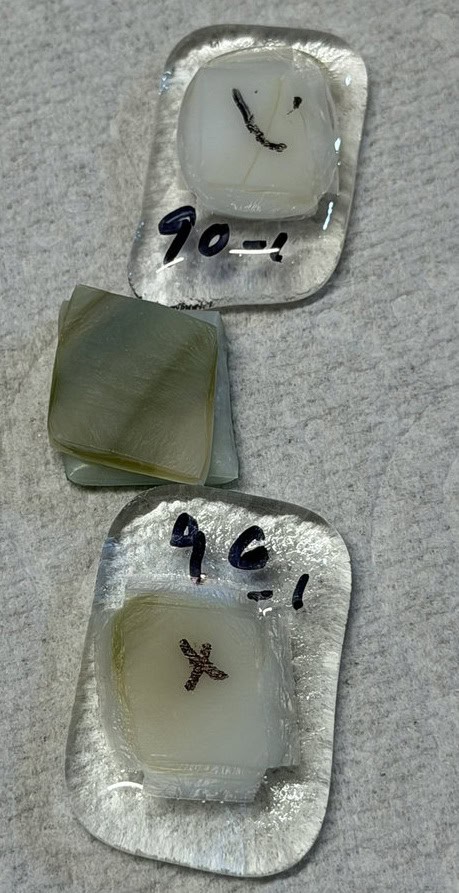

The best way to test glass for COE compatibility is by using polarizing film. To do this, you sandwich your fused test piece between two layers of polarizing film and hold it over a bright light source. If the glass is compatible and stress-free, it will appear clear with no visible halo or color pattern. But if you see a light halo or rainbow-like stress lines around the glass, that’s a sign of internal tension — meaning the glasses have different coefficients of expansion and are not compatible. The reason this works is that stressed glass bends light differently than stress-free glass. The polarizing film reveals those light distortions, making hidden internal stress visible to the eye. It’s a simple, inexpensive test that provides a huge amount of confidence before committing mystery glass to a larger fused project.

Testing glass for compatibility may feel like an extra step, but it’s one of the most valuable habits a fused glass artist can develop. A few small test tiles and a quick check with polarizing film can save hours of work, prevent cracked pieces, and open the door to experimenting safely with new and reclaimed glass. I actually enjoy this part of the process — a little mix of art and science in the kiln. Every test teaches me something new, and that knowledge carries forward into stronger, more reliable, and more creative fused glass work. And not all glass work is about making beautiful, finished pieces — sometimes the most important work we do in the studio is testing, learning, and understanding the material that makes our art possible.

If you would like to see more of my fused glass work, please refer to my website Elegant Fused Glass by Karen. If you get a chance, check out all my site and my Elegant Fused Glass by Karen YouTube. If you would like to stay abreast of what I’m up-to and learn a little more about jewelry, check out our newsletter. It is published the last day of each month.

Keeping my kilns warm,

Karen